About the modeling of the extrusion

In the beginning of my 3D activities I reviewed several slicer and

finally selected Slic3r as my favorite program. Although it is quite user

friendly and quite well documented. Furthermore it is open source, so I

could check open questions within the source code.

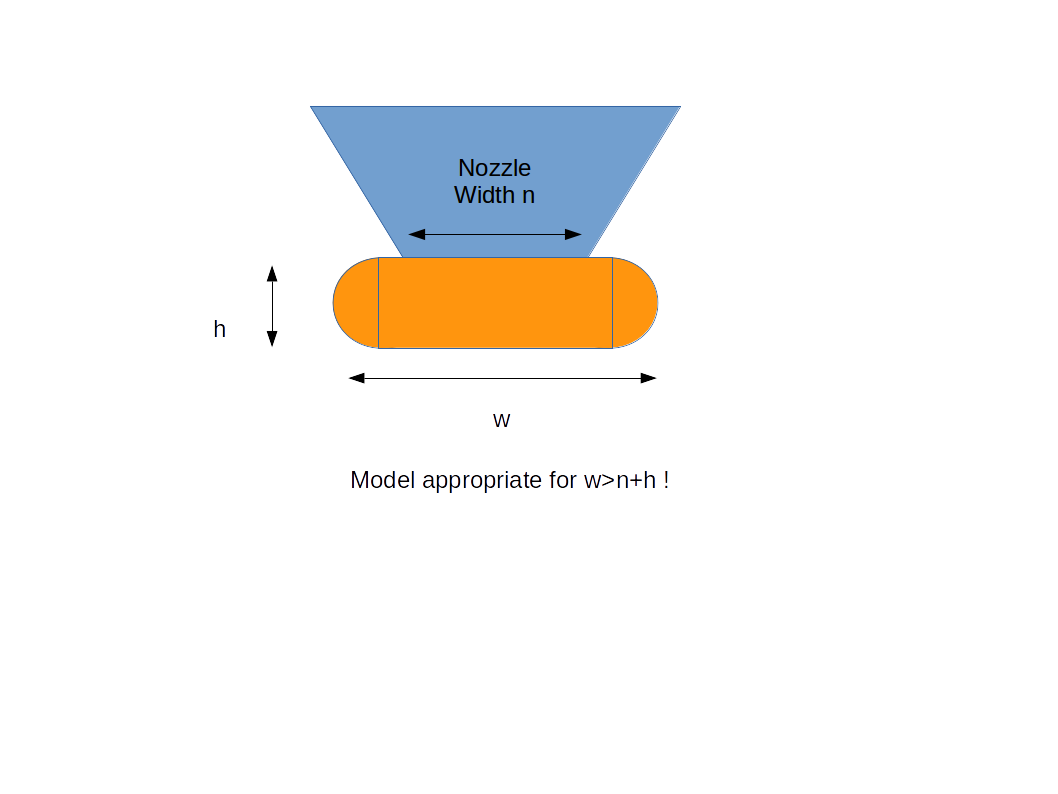

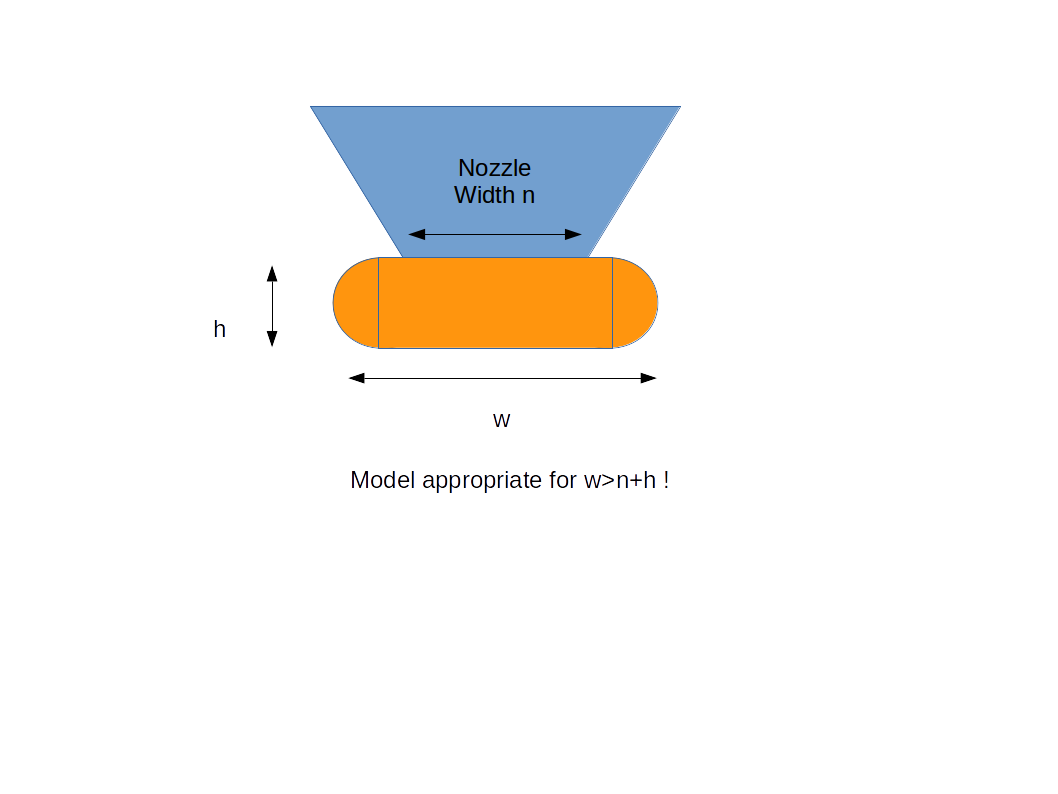

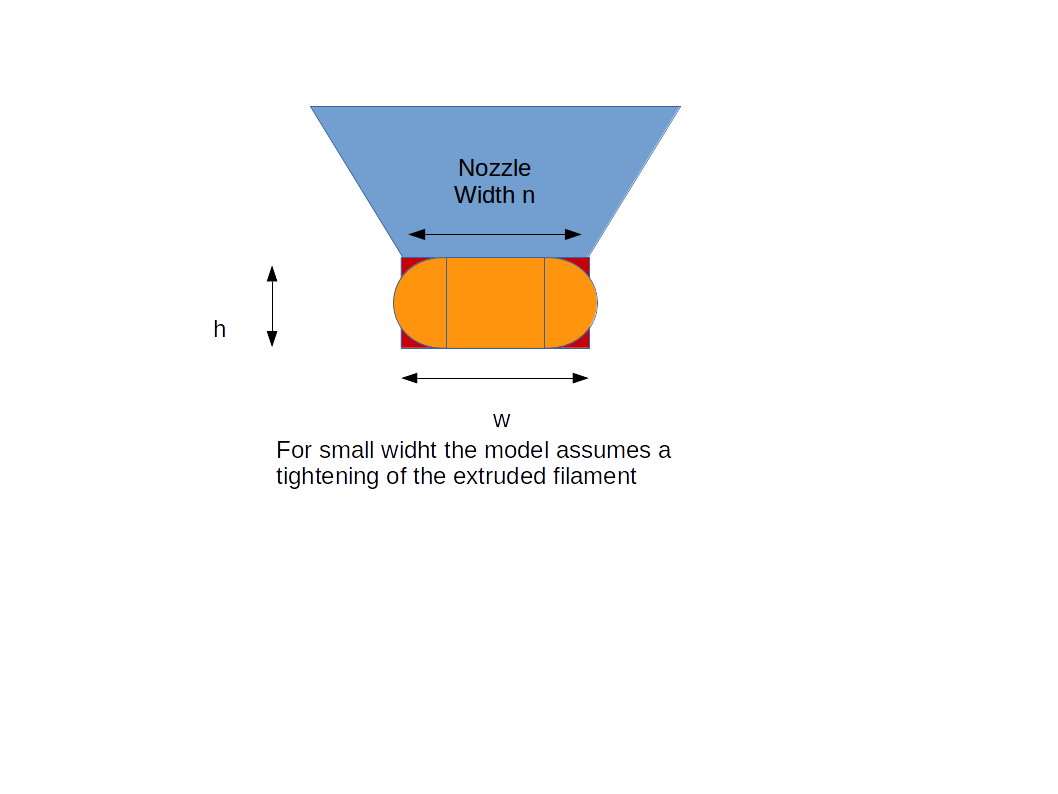

After some first prints with insufficient stability I realized a weakness

in the implemented model for extrusion. When the printed width is smaller

than the nozzle diameter plus height, the calculation of the extruded

material becomes questionable. Unfortunately, this was the commonly used

setting for my prints.

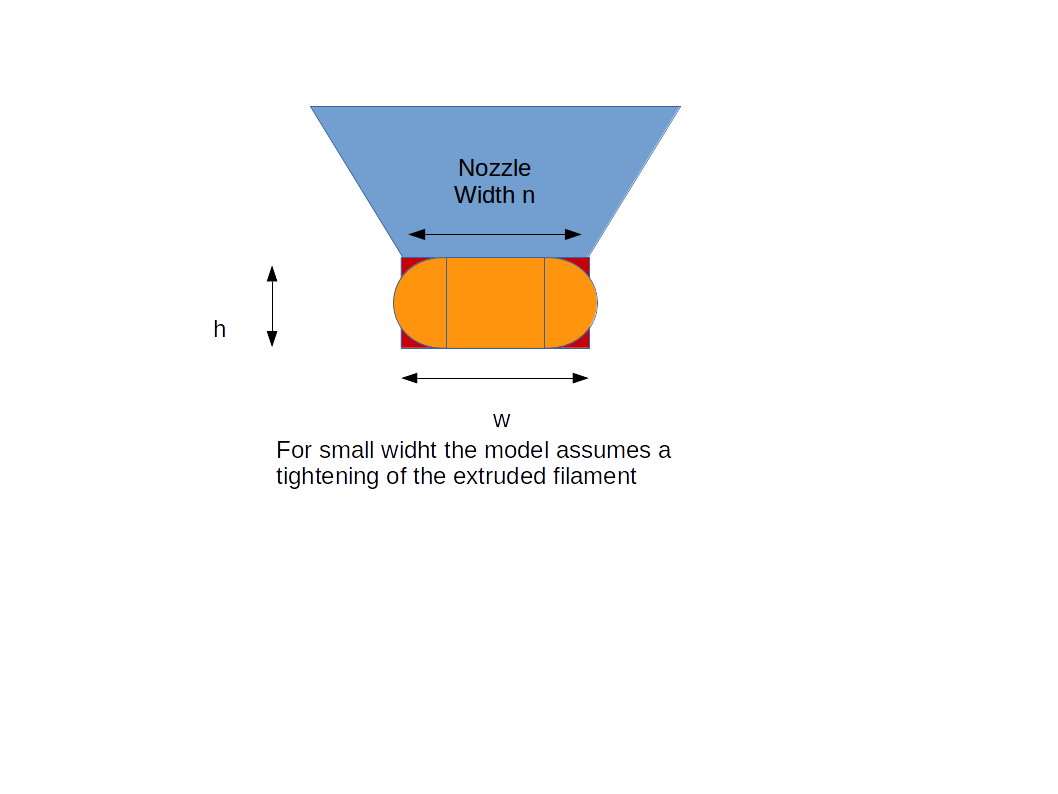

This is a behavior which cannot be that real, since the filament doesn't

know that it must shrink below the nozzle width.

Looking on a real print it can be seen, that the outer side of the filament

is rounded, but doesn't show the shape of a semi circle but a segment having

a extend approximately a third of the height.

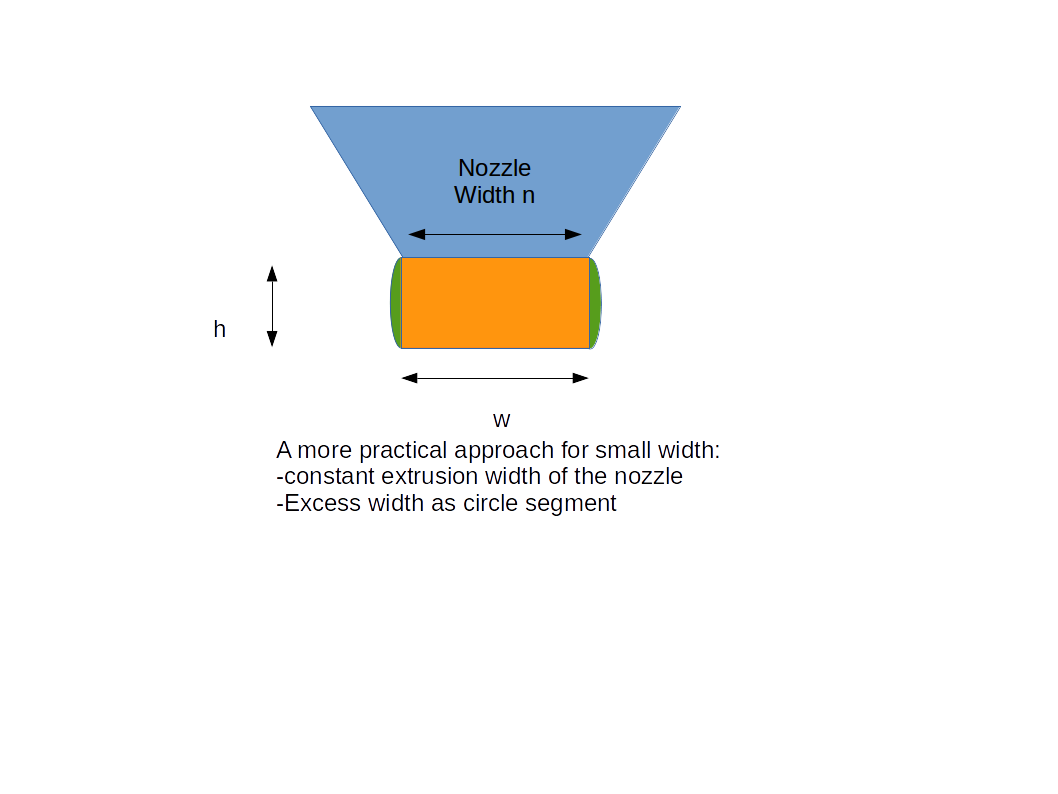

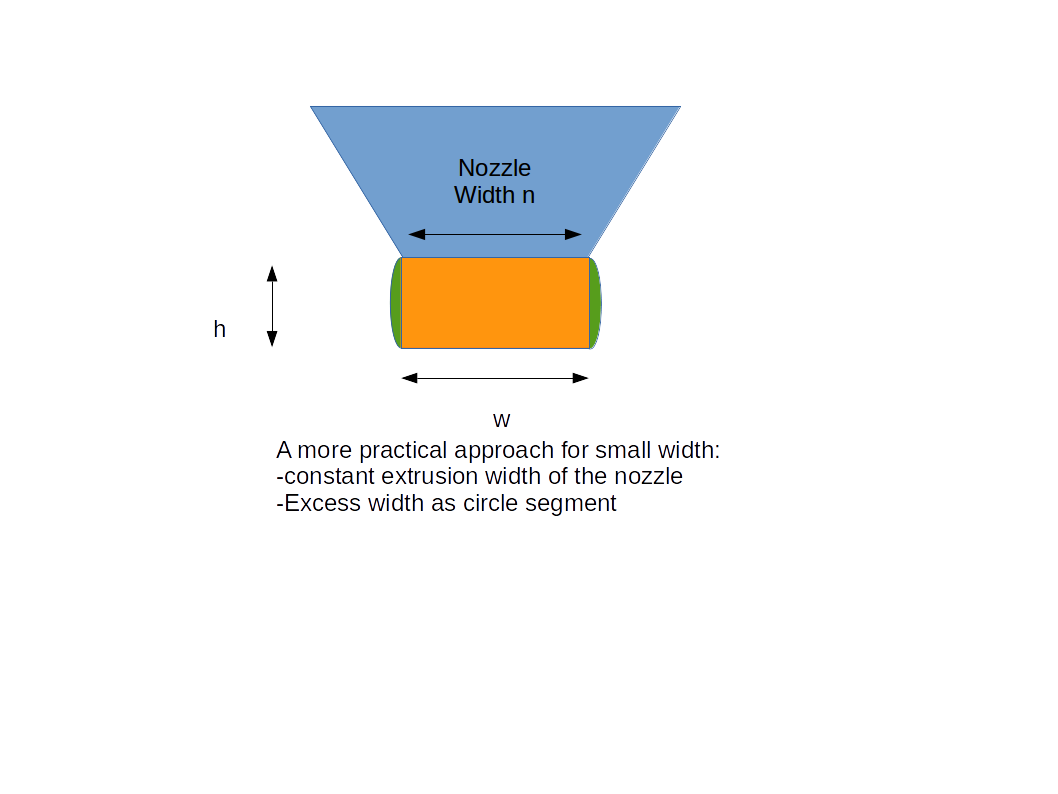

Having this in mind I implemented a modified model for the extrusion

calculation, where the extrusion width is formed by a suitable circle

segment besides the inner extrusion area.

Using this model the material usage for each layer is increasing by a few

percent, providing more material for the 3D print. Thereby moreand larger

junctions are formed to improve the mechanical stability of the objects.

A patch file for the source code (file Flow.cpp in XS/src/libslic3r) can be

found here.