The pressure advance approach

As it came up from the theory that there is a theoretical possibility to

make the filament flow through the nozzle as rectangular as it is

commanded from the slicer. Therefore we need to implement the Dirac delta

function. The easiest approach is to push the filament a certain value

before the main extrusion starts with the highest possible speed.

This is the approach which is implemented in the firmware. It has to be

in the firmware because if it is commanded from outside you have a delay

due to the command chain which is counteracting for this effect.

For each extrusion segment the "pressure" is calculated as the amount of

steps by the given extrusion rate rext and a factor k as

psteps

= rext * k

These steps are applied immediately before an extrusion step starts or

directly after an extrusion step stops (in the opposite direction as

pressure relaxation). In practice this procedure is limited by the slip of

the extruder. Forcing the extruder to push the maximum speed possible will

end up in a slipping of the filament because we are acting against the

nozzle forces and have to provide in short time an extremely high speed.

Therefore I introduced a delay which is acting as a brake for the pressure

building up. Between each pushing step this delay (in microseconds) bill

be applied, slowing down the pressure build up to a measure where the slip

no longer occurs.

So with two parameters the pressure advance mechanism is implemented in the

firmware. I selected a rarely used gcode number for the programming of this

mechanism:

M214 Ex Ky Dz

with x the extruder indicator (0 or 1), K the factor and D the delay

time.

So far the implemented algorithm. But how do we get the correct parameters?

This was the tricky thing and I solved it in this way:

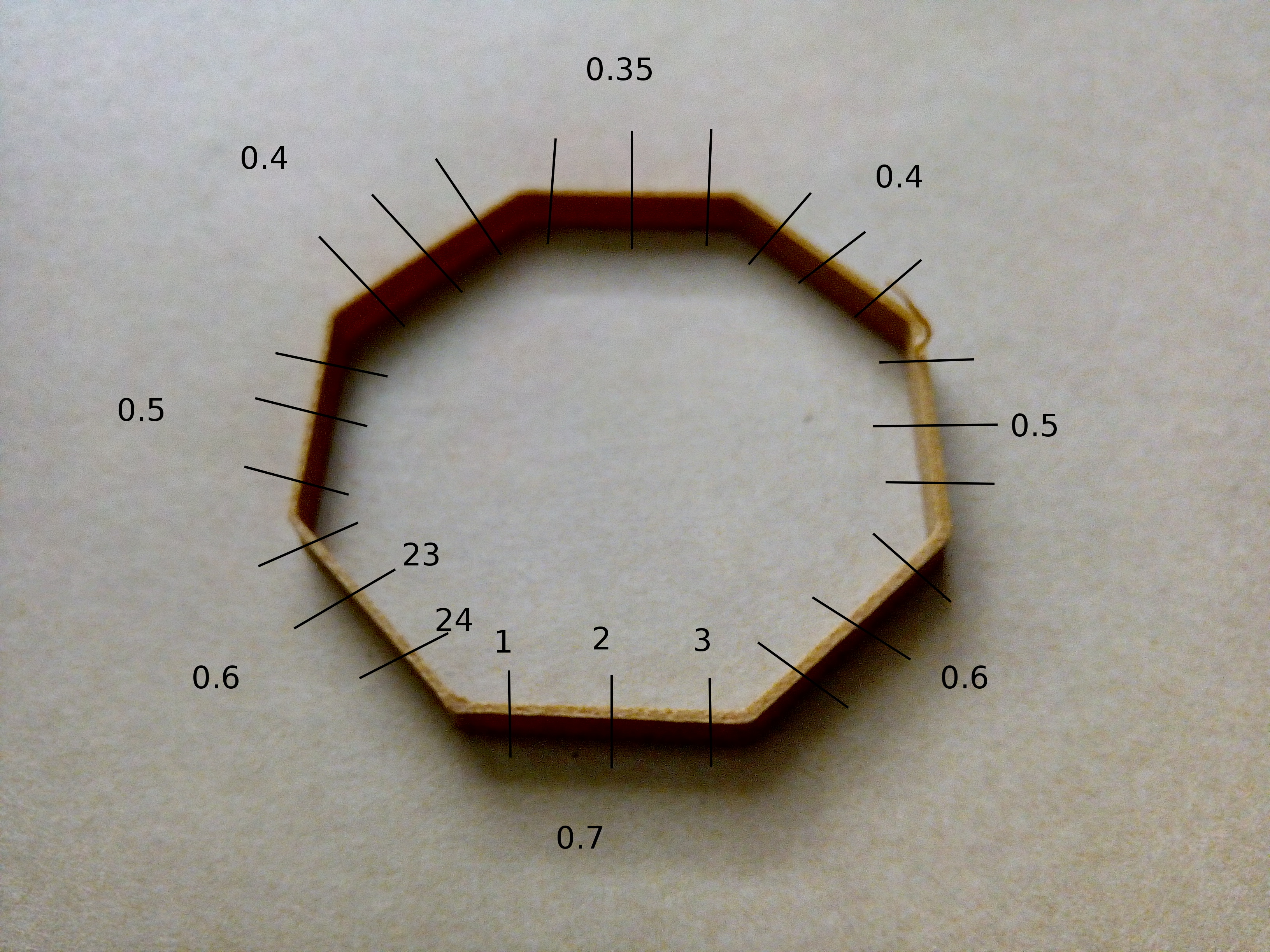

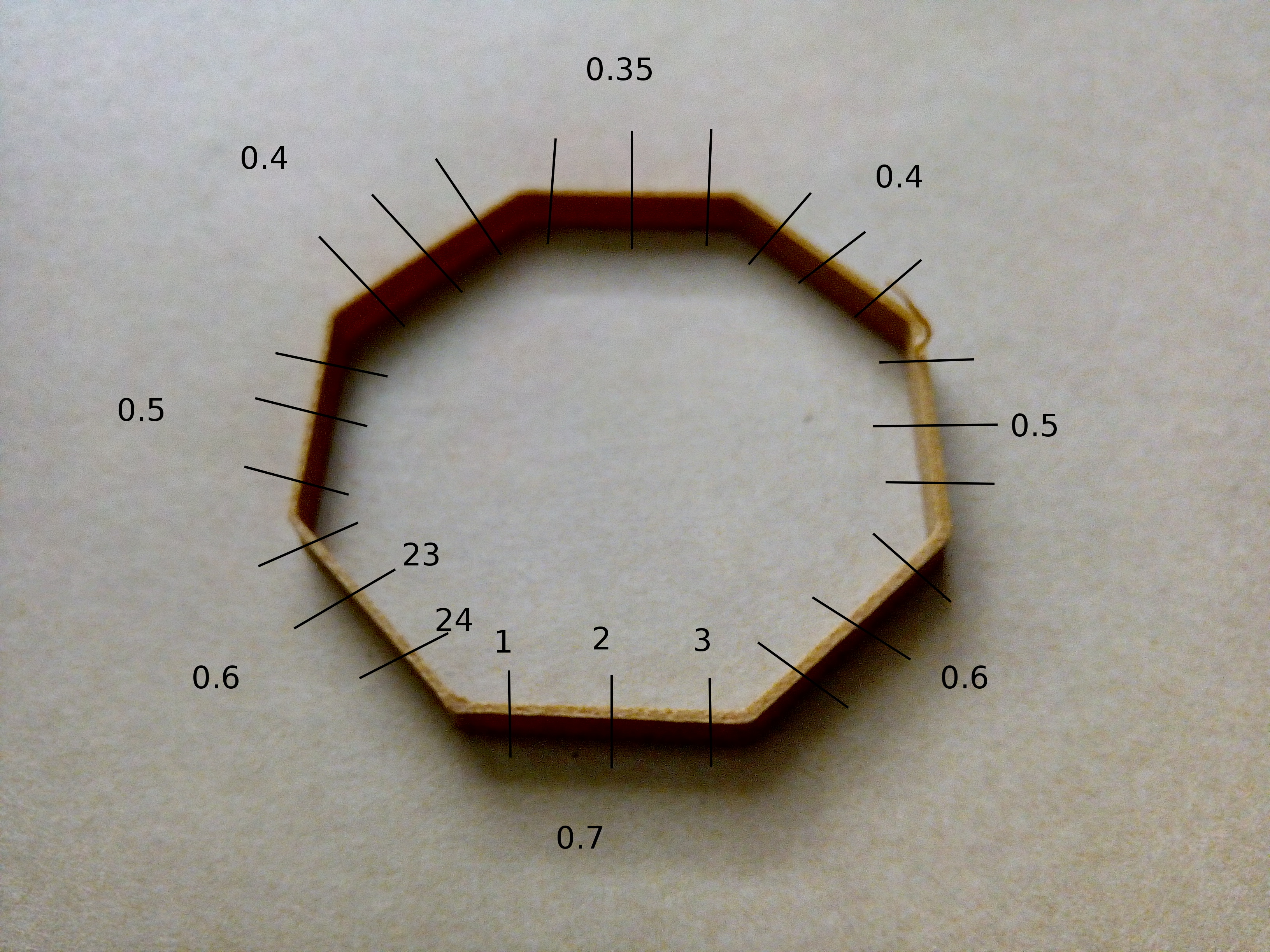

First of all we need a proper test structure. It should vary the extrusion

rate in a definite way and provide a possibility to measure the result. I

selected an octagon structure, which can fulfill these demands. In the

picture below you can see how this is done in detail.

The octagon is printed as a single line counter clock wise. On

the outer side you can see the dimensions of the nominal line width and the

measurement positions for each segment. By this approach I can see the

impact ton falling and rising values of the line width.

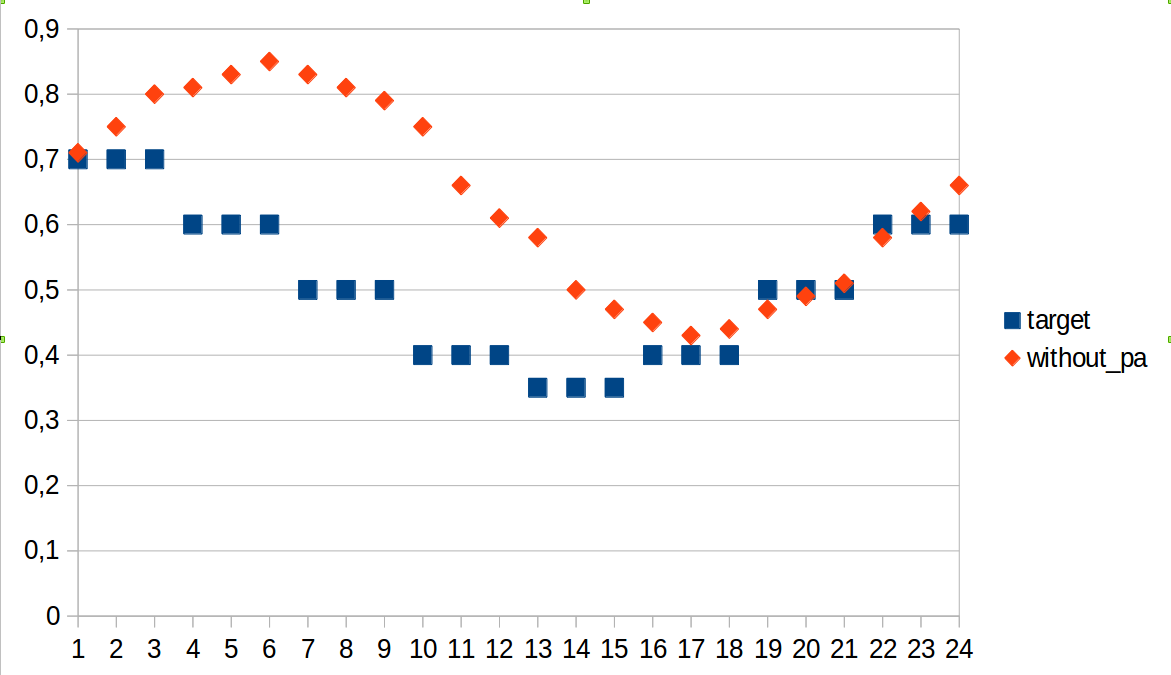

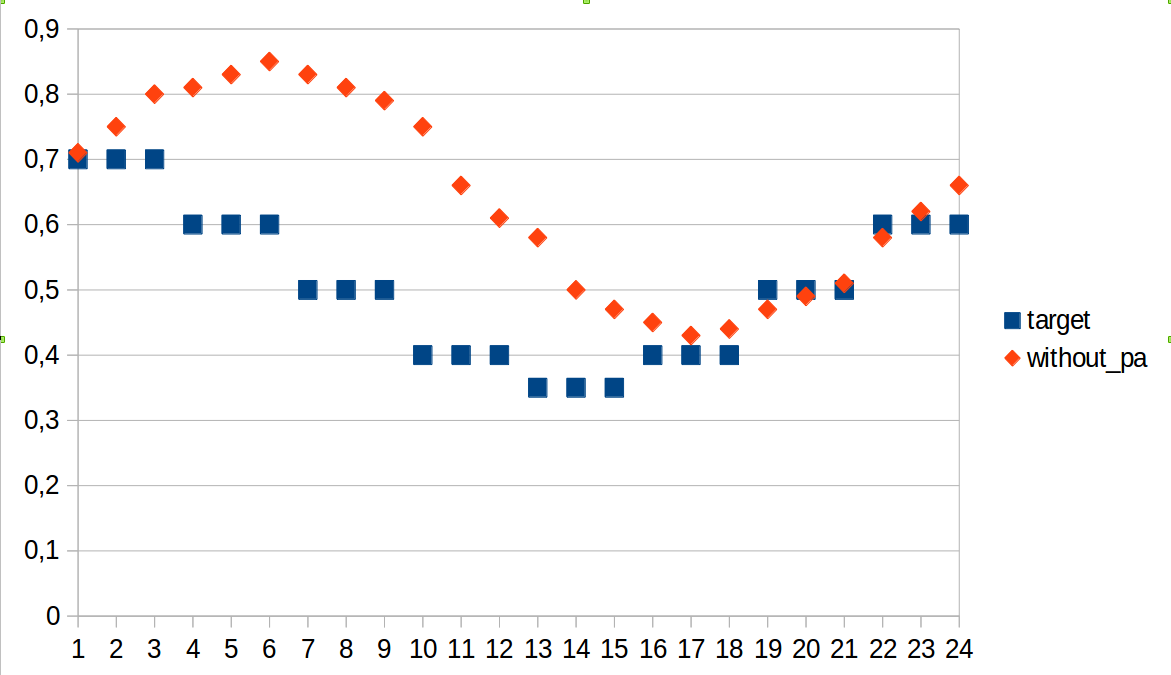

The result is quite impressive (and furthermore found on direct extruder

hardware too): You can see the shift between the commanded (blue dots) and

the real (orange points) flow.

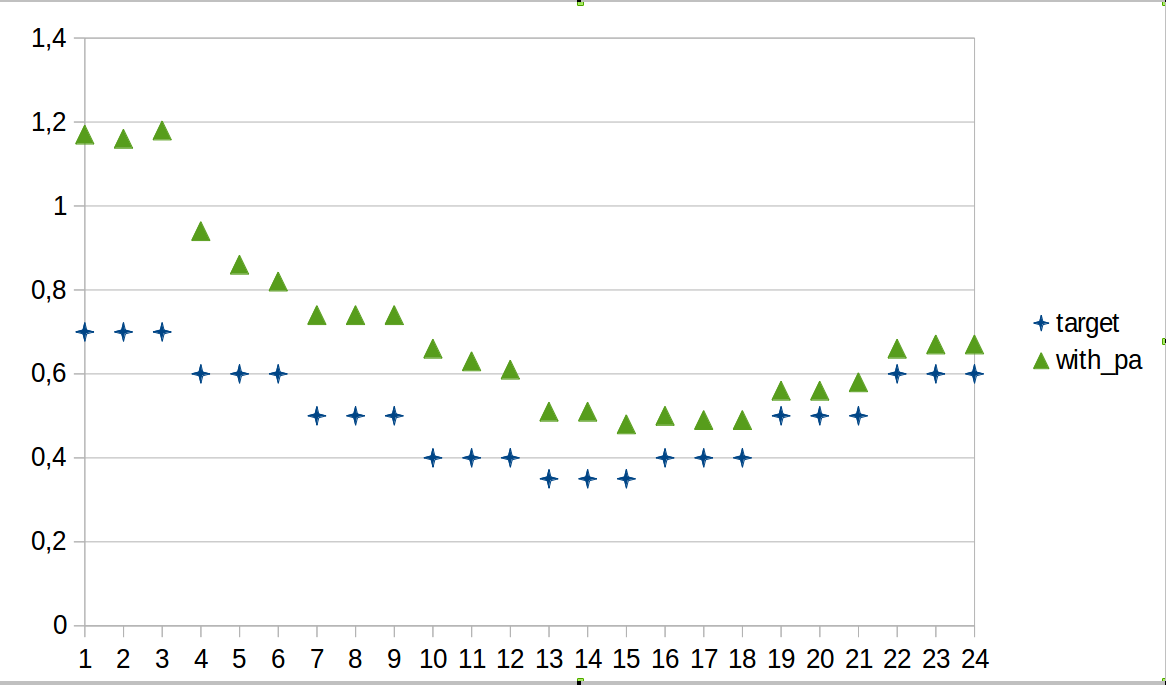

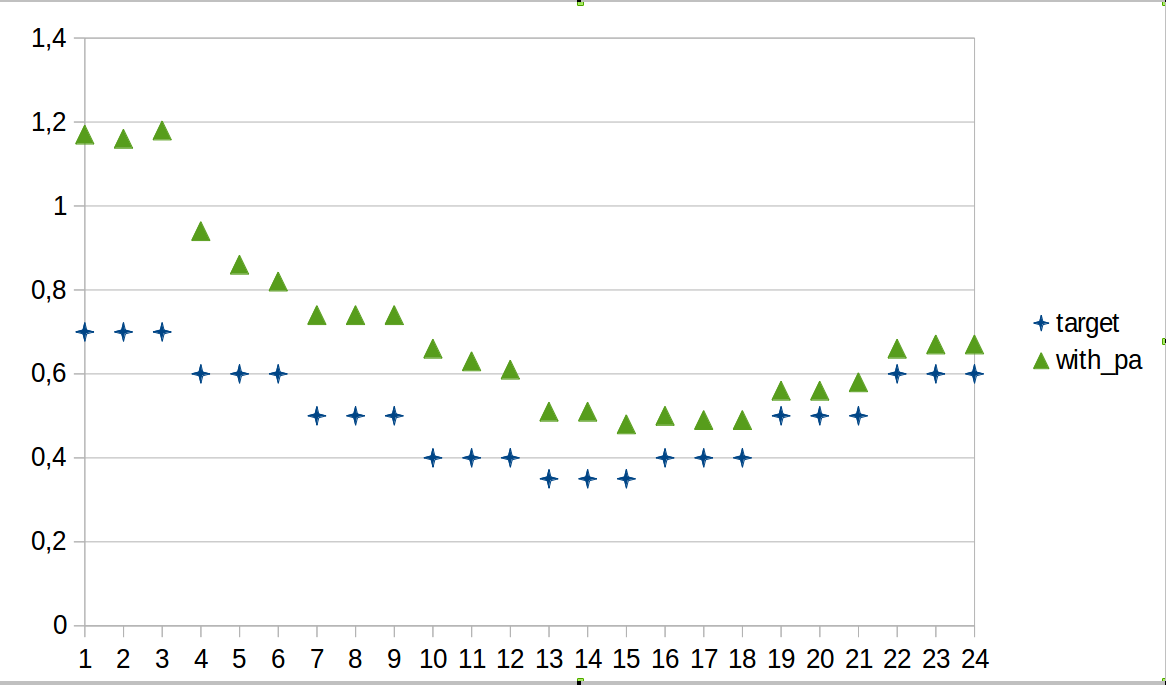

With the presented test structure it is now possible to set the parameter

for the pressure advance mechanism in the firmware . By adjusting the K

factor it is possible to achieve a test print which looks like below:

One comment to the offset found on both graphs: although the material flow

is the same for each layer, the deposition will be statistically spread

below the nozzle. The material deposition is not guided on the side, so the

material will flow freely. This spread on the lateral dimension is

generating the offset found in the graph. Furthermore, these values are

taken only from the upper half of the test print to avoid some

irregularities on the first layer.

To generate the necessary gcode I prepared a calculation table, which can be exported as

text file ( cell separator: space, no text identifier) and occasionally

exchange the commas by dots. This file can be directly printed with

the extension ".gcode". The entries marked in orange may be adopted to the

valid settings for your printer and material.

For the most tested materials I got good results with K-values between 90

and 150, the delay for my printer is D100 for all material up to now, I

didn't put too much effort to optimize this value, it works.

Finally a warning for all tester: this algorithm is experimental and

up to now sensitive on buffer underrun. Printing the test structur from

external source like octoprint is running smoothly, structures with lot of

small segments like circles or other irregular shapes will easily

generate a buffer underrun since the transfer rate of the USB is still too

low. Therefore I'm always printing from SD-Card.

I faced some print stops when octoprint is running in parallel, which I have

to evaluate further. So my recommendation is to print with pressure advance

as stand alone printer without interrupting by USB requests yet. Support for

improvement is welcome every time.