A look to the theory can give us a hint how to determine the optimal temperature for the filament. From the supplier of the filaments one can get in best case the melting temperature of the material, a common value is a temperature range as preferred operation point. However, sometimes there are temperatures outside of this range reported in the community, so how much can we trust these values?

From my point of view: they are some starting points. Due to different hardware configurations and tolerances of the critical parts you cannot rely on any reported value but you have to find your own setting. This is more critical for the K8400, there the thermal coupling between temperature sensor and hotend is quite poor and extremly dependant on tolerances. But the temperature is driving one essential parameter of the 3D print: the viscosity of the melted filament.

The viscosity µ is strongly temperature dependant and is one of the parameters impacting the time constant of the extrusion differential equation

Vext - Afil/Anoz*Vnoz = (const * µ* Anoz * lhot/Ehot) * dVnoz/dt

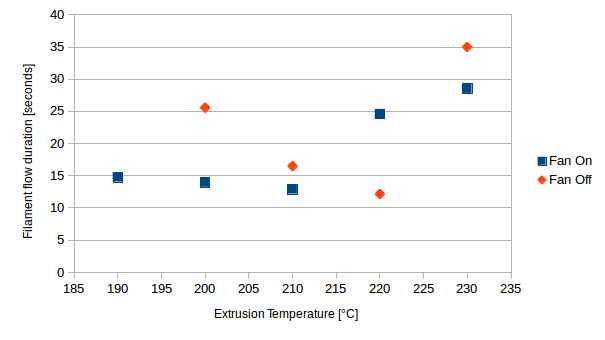

With increasing temperature the viscosity is decreasing, reducing the time for the ramp up and ramp down of the material flow in the nozzle. That means, when we do an extrusion of a defined time ( or length), the material flow through the nozzle will stop earlier at higher temperatures.

This effect can be observed quite good for most of the materials, but at a certain temperature the material flow won't stop. Here we are at the limit of the theory, because we cannot neglect any longer another applied force: the graviation. There is for the most materials a temperature, where the material becomes so liquid, that the own weight of the material generates sufficient pressure in the nozzle to flow though it without filament extraction. In this case the material flow stops just after all the liquified material is gone. For the subsequent filament extrusion you will consequently have no material flow through the nozzle, because the volume in the hotend has to be filled up again. This is a condition, which we have to avoid for a proper 3d print.

But this shows the possible way to find the right temperature setting for the filament.

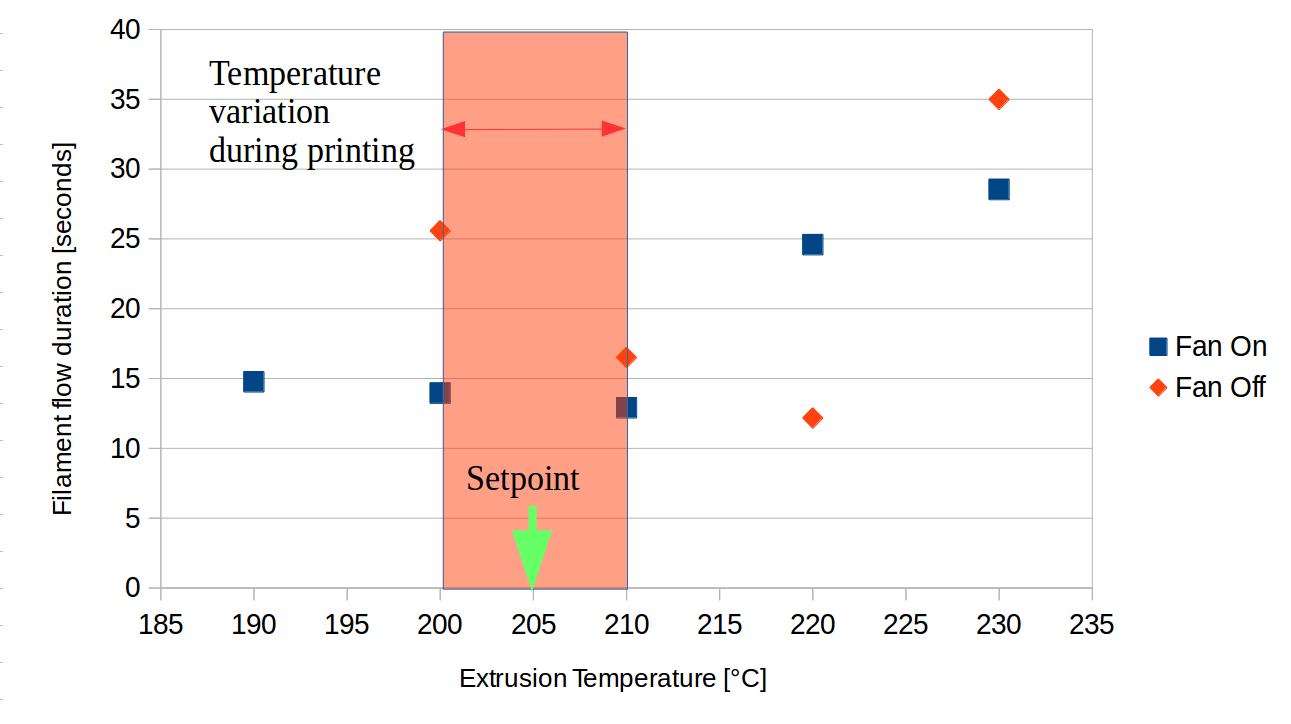

However, having an optimized temperature control, this procedure will

generate curves independent from the fan operation.

To support this evaluation process I implemented in the firmware a new menu: under the control settings an "advanced" selector will appear, where you can set the temperature of the nozzle and afterwards use the stopwatch menu to measure an extrusion cycle. With the start of the stopwatch 5mm filament will be pushed. you can observe the extrusion flow and decide according tho the speed when the extrusion is stopped. Then, after pressing the stop menu, the time for the extrusion cycle is displayed. Take 5 to 10 measurements at each temperature and calculate the mean value of these observation and you will get a similar behavior like shown above.

The operating extrusion temperature shall be 5°C to 10°C below the lowest extrusion time. It is mainly dependent on the temperature stability over the various operation conditions like running extrusion, fan operation. Using a tuned temperature control from my firmware modification the temperature variation is well below 5°C. Take your observed temperature variation during the printing and put this band below the onset of the gravitational flow. The center of this band should be your setpoint for the extrusion temperature.

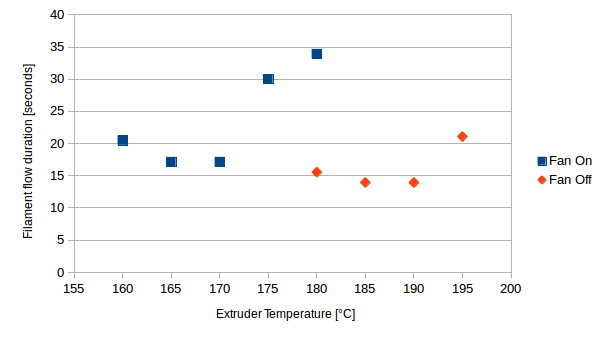

When testing several material you will find out that each materials have

their own specific behavior setpoint according to this procedure. Even for

PLA you will find significant differences between suppliers, but for

different colors too.